The fitness industry has witnessed tremendous growth in recent years, with yoga becoming one of the most popular forms of exercise worldwide. As studios and retailers strive to meet increasing demand while maintaining competitive pricing, many are turning to OEM yoga mat partnerships as their preferred sourcing strategy. This business model offers unprecedented flexibility, cost efficiency, and quality control that traditional wholesale purchasing simply cannot match.

The shift toward OEM yoga mat manufacturing partnerships represents a fundamental change in how fitness businesses approach product sourcing. Rather than accepting pre-made products with limited customization options, studios and retailers are discovering the immense value of working directly with manufacturers to create products that align perfectly with their brand identity and customer needs.

Understanding why this trend has gained such momentum requires examining the multiple advantages that OEM yoga mat partnerships provide. From cost savings and quality assurance to brand differentiation and market responsiveness, these collaborations offer solutions to many of the challenges that plague traditional retail models in the competitive fitness equipment market.

Cost Efficiency and Profit Margin Optimization

Elimination of Middleman Markups

One of the most compelling reasons studios and retailers gravitate toward OEM yoga mat partnerships is the significant cost reduction achieved by eliminating intermediary markups. Traditional supply chains often involve multiple layers of distributors, wholesalers, and importers, each adding their profit margin to the final price. By working directly with manufacturers, businesses can reduce product costs by 30-50% compared to traditional wholesale purchasing.

This direct relationship allows retailers to access factory pricing while maintaining control over quality specifications. The savings can be reinvested into marketing, facility improvements, or passed on to customers as competitive pricing. Many successful yoga studio chains have built their expansion strategies around the cost advantages provided by OEM yoga mat manufacturing partnerships.

Furthermore, the transparency in pricing that comes with direct manufacturer relationships enables better financial planning and inventory management. Retailers can forecast costs more accurately and negotiate volume discounts that would be impossible through traditional distribution channels.

Scalable Pricing Models

OEM partnerships offer flexible pricing structures that adapt to business growth and seasonal fluctuations. Unlike fixed wholesale pricing, OEM yoga mat manufacturers typically provide tiered pricing based on order volumes, allowing small studios to start with modest quantities while benefiting from lower per-unit costs as they grow.

This scalability proves particularly valuable for businesses experiencing rapid expansion or those operating in markets with seasonal demand patterns. Retailers can adjust order quantities without being locked into rigid minimum order requirements that characterize many wholesale relationships.

The ability to negotiate custom payment terms and production schedules further enhances the financial flexibility that OEM yoga mat partnerships provide, enabling businesses to align cash flow with revenue cycles more effectively.

Quality Control and Customization Advantages

Direct Quality Oversight

Quality control represents a critical concern for any business selling fitness equipment, particularly items like yoga mats that directly impact user safety and satisfaction. OEM yoga mat partnerships enable retailers and studios to implement comprehensive quality assurance programs that would be impossible with pre-manufactured products.

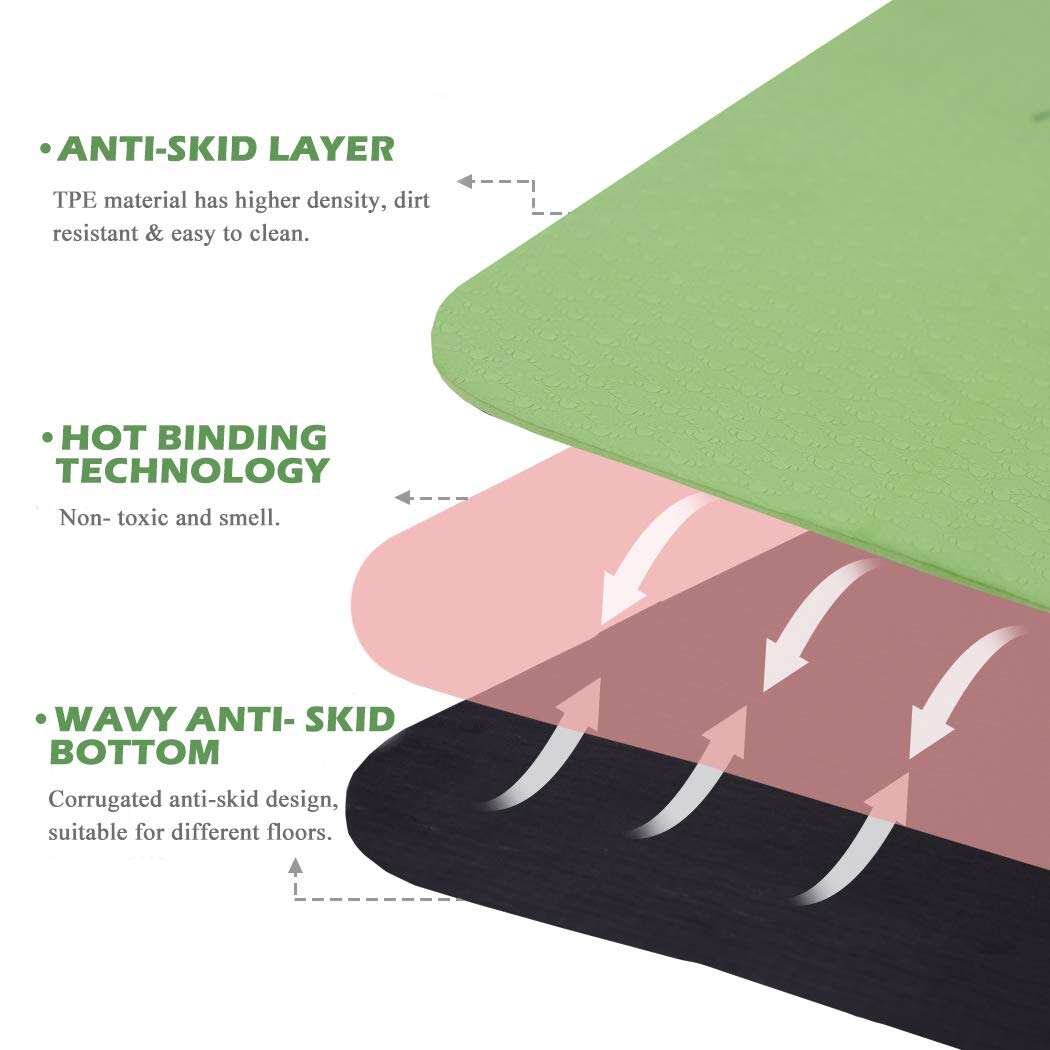

Through direct manufacturer relationships, businesses can specify exact material compositions, thickness tolerances, grip requirements, and durability standards. This level of control ensures that every OEM yoga mat meets the specific needs of their target market, whether that involves extra cushioning for therapeutic yoga or enhanced grip for hot yoga practices.

Regular factory visits and third-party quality inspections become standard practice in OEM relationships, providing unprecedented visibility into production processes. This transparency builds confidence in product quality and enables rapid response to any manufacturing issues that might arise.

Brand-Specific Customization Options

The customization capabilities offered through OEM yoga mat partnerships extend far beyond simple logo placement. Manufacturers can incorporate unique color schemes, proprietary material blends, custom packaging, and even specialized features that differentiate products in competitive markets.

Studios often leverage these customization options to create signature product lines that reinforce their brand identity and teaching philosophy. For example, a studio specializing in restorative yoga might specify extra thickness and cushioning, while a hot yoga facility might prioritize superior moisture absorption and bacterial resistance.

Retailers benefit from the ability to create exclusive product lines that cannot be found elsewhere, providing competitive advantage and customer loyalty benefits. The level of customization available through OEM yoga mat manufacturing enables true product differentiation in an increasingly commoditized market.

Supply Chain Control and Reliability

Inventory Management Optimization

Managing inventory effectively requires balancing customer demand with storage costs and cash flow constraints. OEM yoga mat partnerships provide superior inventory management capabilities through flexible production scheduling and just-in-time manufacturing options.

Unlike wholesale relationships where businesses must purchase large quantities to achieve favorable pricing, OEM partnerships allow for smaller, more frequent orders that align with actual demand patterns. This approach reduces carrying costs while ensuring adequate stock levels to meet customer needs.

The predictable lead times and production schedules that characterize well-managed OEM yoga mat relationships enable more accurate demand forecasting and reduce the risk of stockouts or overstock situations that can significantly impact profitability.

Geographic and Logistical Advantages

Strategic partnerships with OEM yoga mat manufacturers often include comprehensive logistics support that extends beyond simple product manufacturing. Many OEM partners provide warehousing, drop-shipping, and distribution services that can significantly reduce operational complexity for retailers and studios.

This integrated approach to supply chain management enables businesses to focus on their core competencies while leveraging their manufacturing partner's expertise in production and logistics. The result is often improved efficiency and reduced total cost of ownership compared to managing multiple vendor relationships.

Geographic proximity to manufacturing facilities can provide additional advantages in terms of reduced shipping costs and faster response times for urgent orders. Many successful retailers strategically select OEM yoga mat partners based on logistical considerations as well as manufacturing capabilities.

Market Responsiveness and Innovation

Rapid Product Development Cycles

The fitness industry evolves rapidly, with new trends, materials, and consumer preferences emerging regularly. OEM yoga mat partnerships enable businesses to respond quickly to market changes through accelerated product development cycles that would be impossible with traditional wholesale relationships.

When new materials like eco-friendly TPE compounds or innovative grip technologies become available, OEM partners can integrate these advances into production runs within weeks rather than months. This responsiveness provides significant competitive advantages in markets where being first to offer new features can capture substantial market share.

The collaborative relationship between retailers and OEM yoga mat manufacturers often leads to genuine innovation, with manufacturers incorporating feedback from end users to develop improved products that benefit the entire industry.

Trend Adaptation and Market Intelligence

Experienced OEM yoga mat manufacturers work with multiple clients across different markets, providing valuable intelligence about emerging trends and consumer preferences. This insight helps retailers and studios make informed decisions about product specifications and market positioning.

The ability to quickly adapt products to meet changing consumer demands represents a crucial advantage in the competitive fitness equipment market. Whether responding to increased demand for sustainable materials or incorporating new safety features, OEM partnerships enable rapid market adaptation.

Long-term relationships with OEM yoga mat manufacturers often evolve into strategic partnerships where both parties collaborate on market research and product development initiatives that benefit all stakeholders in the supply chain.

Risk Management and Business Continuity

Quality Assurance and Liability Protection

Professional liability and product quality concerns represent significant risks for any business selling fitness equipment. OEM yoga mat partnerships typically include comprehensive quality assurance programs and liability protections that reduce these risks compared to purchasing products through traditional wholesale channels.

Reputable OEM manufacturers maintain product liability insurance and implement rigorous testing protocols that ensure compliance with relevant safety standards. This protection extends to their retail partners, providing an additional layer of security that independent retailers particularly value.

The documentation and traceability that accompany professionally managed OEM yoga mat production processes also support regulatory compliance and provide clear chains of responsibility in the unlikely event that product issues arise.

Supply Chain Diversification

Diversifying supply sources represents a fundamental risk management strategy, particularly important given recent global supply chain disruptions. OEM yoga mat partnerships enable businesses to develop relationships with multiple manufacturers while maintaining consistent quality standards across their product lines.

This diversification provides resilience against manufacturing disruptions, natural disasters, or geopolitical events that might affect individual suppliers. The flexibility to shift production between qualified OEM partners ensures business continuity even during challenging circumstances.

Furthermore, the direct relationships cultivated through OEM yoga mat partnerships often provide preferential treatment during periods of high demand or supply constraints, ensuring that established partners receive priority allocation of manufacturing capacity.

FAQ

What minimum order quantities are typically required for OEM yoga mat partnerships

Minimum order quantities for OEM yoga mat partnerships vary significantly based on customization requirements and manufacturer capabilities. Most reputable manufacturers require initial orders of 500-1000 pieces for basic customization like logo printing, while complex custom specifications might require 2000-5000 pieces minimum. However, many manufacturers offer graduated pricing that becomes more favorable as order quantities increase, making it possible for smaller businesses to start with modest quantities and scale up as demand grows.

How long does the typical OEM yoga mat production process take from order to delivery

Production timelines for OEM yoga mat manufacturing typically range from 15-45 days depending on order complexity and manufacturer capacity. Simple customizations like logo printing or basic color changes usually require 15-25 days, while complex specifications involving new material formulations or specialized features might take 30-45 days. Experienced manufacturers often provide detailed production schedules that account for material procurement, manufacturing, quality control, and shipping logistics.

What quality certifications should retailers look for in OEM yoga mat manufacturers

Quality certifications for OEM yoga mat manufacturers should include ISO 9001 for quality management systems, along with relevant safety certifications such as CE marking for European markets or CPSIA compliance for products sold to consumers with children. Environmental certifications like GREENGUARD or OEKO-TEX become increasingly important as consumers demand eco-friendly products. Additionally, manufacturers should provide material safety data sheets and comply with relevant chemical restriction regulations in target markets.

Can small yoga studios benefit from OEM partnerships or are they only suitable for large retailers

Small yoga studios can definitely benefit from OEM yoga mat partnerships, though the approach might differ from large retailers. Many manufacturers offer flexible programs designed for smaller businesses, including group purchasing options where multiple small studios combine orders to achieve better pricing. Some OEM partners specialize in serving smaller clients and offer lower minimum order quantities along with extended payment terms. The key is finding manufacturers who understand the unique needs of small businesses and can provide appropriate support and flexibility.

Table of Contents

- Cost Efficiency and Profit Margin Optimization

- Quality Control and Customization Advantages

- Supply Chain Control and Reliability

- Market Responsiveness and Innovation

- Risk Management and Business Continuity

-

FAQ

- What minimum order quantities are typically required for OEM yoga mat partnerships

- How long does the typical OEM yoga mat production process take from order to delivery

- What quality certifications should retailers look for in OEM yoga mat manufacturers

- Can small yoga studios benefit from OEM partnerships or are they only suitable for large retailers