The fitness industry continues to experience unprecedented growth, with wholesale distributors seeking reliable equipment that delivers both quality and profitability. OEM yoga balls have emerged as one of the most strategic product categories for distributors looking to establish strong market positions. These versatile fitness tools offer exceptional profit margins while meeting the diverse needs of gyms, fitness studios, physical therapy clinics, and retail customers across multiple market segments.

Understanding the OEM Yoga Ball Market Landscape

Market Demand and Growth Projections

The global fitness equipment market has witnessed remarkable expansion, with yoga and pilates equipment representing a significant portion of this growth. OEM yoga balls specifically have captured substantial market share due to their affordability, versatility, and accessibility to users of all fitness levels. Market research indicates that the demand for these products continues to rise as more consumers embrace home fitness routines and commercial facilities expand their equipment offerings.

Wholesale distributors who recognize this trend early position themselves advantageously in a competitive marketplace. The consistent demand for OEM yoga balls across multiple customer segments creates stable revenue streams while offering opportunities for volume-based pricing strategies. This market stability makes these products particularly attractive for distributors seeking predictable inventory turnover and customer retention.

Versatility Across Market Segments

The versatility of OEM yoga balls extends their appeal beyond traditional yoga practitioners to include physical therapy patients, prenatal fitness participants, office workers seeking ergonomic solutions, and children in educational settings. This broad application range enables distributors to target multiple customer bases simultaneously, reducing market risk while maximizing sales opportunities.

Commercial fitness facilities particularly value OEM yoga balls for their durability and cost-effectiveness when purchasing in bulk quantities. Home fitness enthusiasts appreciate the space-saving design and multi-functional capabilities that allow for comprehensive workout routines without requiring extensive equipment collections. This cross-market appeal translates directly into increased sales volume for savvy distributors.

Quality Advantages of OEM Manufacturing

Superior Material Standards

OEM manufacturers typically implement stringent quality control processes that ensure consistent product standards across large production runs. When distributors source OEM yoga balls, they receive products manufactured using premium PVC materials that meet international safety standards. These materials undergo rigorous testing for burst resistance, chemical stability, and long-term durability under regular use conditions.

The manufacturing precision achieved through OEM processes results in yoga balls with uniform wall thickness, proper weight distribution, and consistent size specifications. This attention to detail translates into products that perform reliably over extended periods, reducing customer complaints and warranty claims for distributors while building brand reputation in the marketplace.

Advanced Production Technologies

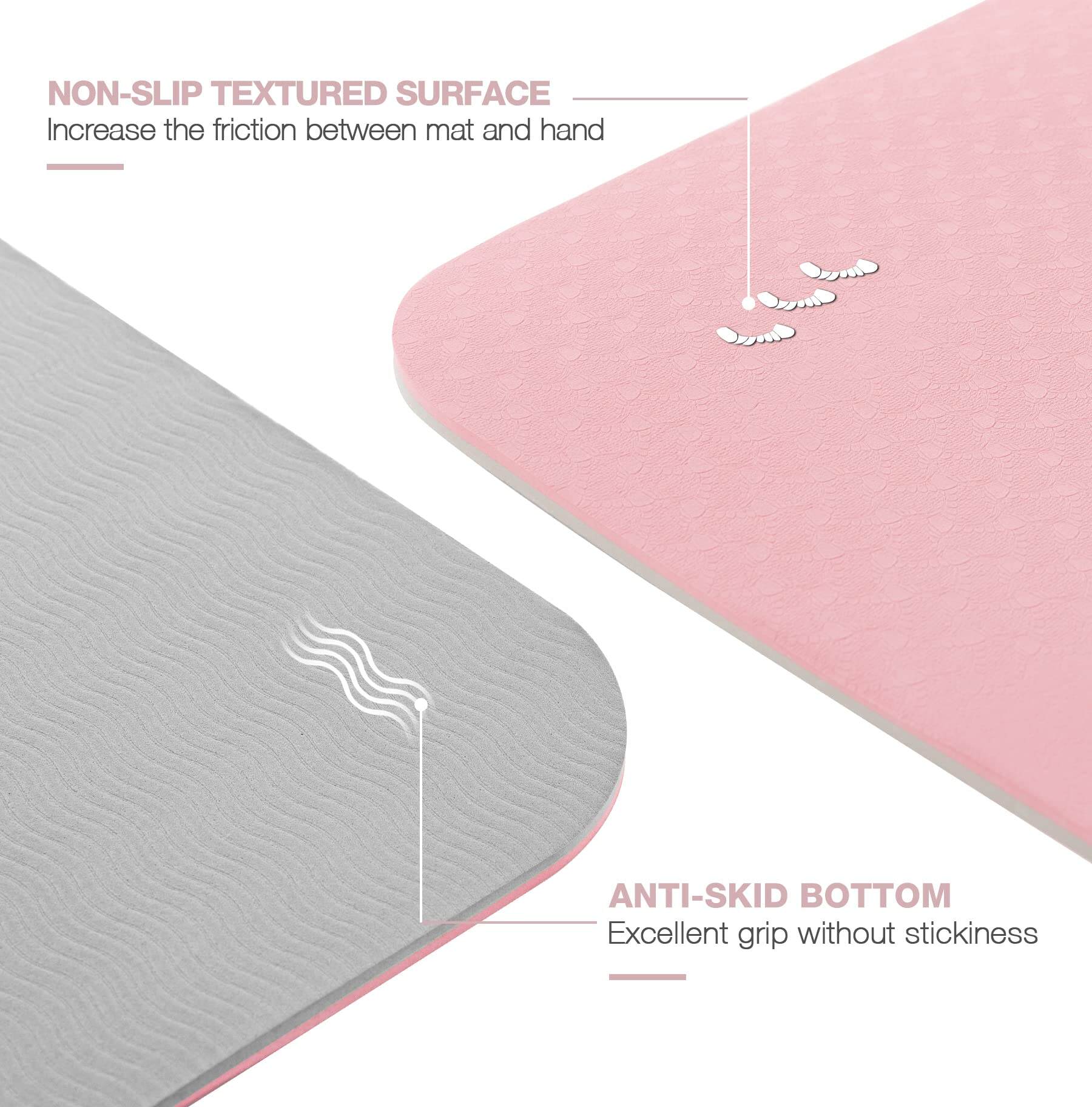

Modern OEM facilities utilize advanced manufacturing technologies that enable precise control over product specifications and quality parameters. Automated production lines ensure consistent seam welding, proper valve installation, and uniform surface texturing that enhances grip and user safety. These technological advantages result in OEM yoga balls that exceed industry standards for performance and longevity.

Quality assurance protocols implemented by reputable OEM manufacturers include pressure testing, material composition verification, and dimensional accuracy checks at multiple production stages. This comprehensive approach to quality management ensures that distributors receive products that meet or exceed customer expectations consistently, supporting long-term business relationships and repeat purchases.

Cost Efficiency and Profit Optimization

Manufacturing Scale Advantages

OEM production enables manufacturers to achieve significant economies of scale that translate into competitive wholesale pricing for distributors. Large production runs reduce per-unit manufacturing costs while maintaining quality standards, allowing distributors to offer attractive pricing to their customers while preserving healthy profit margins. This cost structure advantage becomes particularly pronounced when distributors commit to substantial order quantities.

The efficiency of OEM manufacturing processes also reduces lead times and inventory carrying costs for distributors. Streamlined production schedules enable more predictable delivery timelines, supporting better inventory management and cash flow optimization. These operational efficiencies contribute directly to improved profitability for wholesale distribution businesses.

Customization Without Premium Costs

Many OEM manufacturers offer customization options for yoga balls without the premium pricing typically associated with custom products. Distributors can specify colors, sizes, packaging designs, and even private labeling options while maintaining competitive unit costs. This flexibility enables distributors to differentiate their offerings in crowded markets while building brand recognition among their customer base.

The ability to customize OEM yoga balls extends to technical specifications such as weight capacity, surface texture variations, and included accessories like pumps or exercise guides. These customization capabilities allow distributors to create targeted product offerings for specific market segments while maintaining the cost advantages of volume manufacturing.

Supply Chain Reliability and Logistics

Consistent Production Capacity

Established OEM manufacturers maintain dedicated production capacity that ensures reliable supply availability for wholesale distributors. This production consistency prevents the stock shortages and delivery delays that can damage distributor relationships with their customers. Reliable supply chains become increasingly important as distributors scale their operations and commit to larger customer accounts requiring dependable fulfillment.

Long-term partnerships with OEM manufacturers often include preferential treatment for order scheduling and priority allocation during peak demand periods. These relationships provide distributors with competitive advantages in securing inventory when market demand fluctuates or during seasonal sales peaks common in the fitness industry.

Global Distribution Networks

Leading OEM manufacturers typically maintain extensive distribution networks that facilitate efficient product delivery to wholesale distributors worldwide. These established logistics capabilities reduce shipping costs and delivery times while providing tracking and communication systems that enhance order management efficiency. International shipping expertise becomes particularly valuable for distributors serving diverse geographic markets.

The logistics expertise of OEM manufacturers extends to packaging optimization, customs documentation, and regulatory compliance for international shipments. This comprehensive support reduces administrative burden for distributors while ensuring smooth cross-border transactions and compliance with local regulations in destination markets.

Market Positioning and Competitive Advantages

Brand Development Opportunities

Partnering with OEM manufacturers provides distributors with opportunities to develop private label products that build brand recognition and customer loyalty. Private labeling of OEM yoga balls enables distributors to establish unique market positions while maintaining competitive pricing structures. This brand development strategy creates barriers to direct competition while building valuable intellectual property assets.

The quality consistency of OEM yoga balls supports brand development efforts by ensuring that products bearing distributor brands meet customer expectations reliably. Consistent product performance builds trust and encourages repeat purchases, supporting long-term brand building initiatives and customer relationship development.

Technical Support and Expertise

Reputable OEM manufacturers provide technical support and product expertise that enhances distributor capabilities in serving their customers effectively. This support includes product training, application guidance, and troubleshooting assistance that enables distributors to provide comprehensive customer service. Technical expertise becomes particularly valuable when selling to commercial facilities requiring specific performance specifications.

The research and development capabilities of established OEM manufacturers also provide distributors with early access to product innovations and market trends. This insider knowledge enables proactive inventory planning and strategic market positioning that can provide significant competitive advantages in rapidly evolving fitness markets.

Risk Management and Quality Assurance

Compliance and Safety Standards

OEM manufacturers typically maintain comprehensive compliance programs that ensure their yoga balls meet international safety standards and regulatory requirements. These compliance efforts protect distributors from liability risks while providing marketing advantages in safety-conscious market segments. Proper certifications and testing documentation support distributor sales efforts and customer confidence building.

Regular third-party testing and certification renewal processes maintained by OEM manufacturers provide ongoing assurance of product safety and performance standards. This continuous quality monitoring reduces the risk of product recalls or safety incidents that could damage distributor reputations and financial performance.

Insurance and Warranty Protection

Established OEM manufacturers often provide warranty coverage and insurance protection that reduces financial risks for wholesale distributors. Comprehensive warranty programs demonstrate manufacturer confidence in product quality while providing distributors with tools to address customer concerns effectively. Product liability insurance coverage protects all parties in the distribution chain from potential legal exposure.

The financial stability and insurance coverage maintained by reputable OEM manufacturers provides additional security for distributor partnerships. This stability ensures continued support and service availability throughout the product lifecycle, supporting long-term customer relationships and business continuity planning.

FAQ

What minimum order quantities are typical for OEM yoga balls

Most OEM manufacturers establish minimum order quantities ranging from 500 to 2000 units depending on customization requirements and manufacturer policies. Standard products typically have lower minimums while custom colors or private labeling may require larger initial orders. These quantities enable manufacturers to maintain cost efficiency while providing distributors access to wholesale pricing structures.

How do OEM yoga balls compare to branded alternatives in terms of quality

Quality OEM yoga balls often match or exceed the performance of branded alternatives while offering superior cost efficiency for distributors. Reputable OEM manufacturers use identical materials and production processes as major brands, with the primary difference being marketing and packaging rather than fundamental product quality. Independent testing and certification ensure consistent performance standards.

What customization options are available for wholesale distributors

Common customization options include color selection, size variations, surface texture modifications, packaging design, and private labeling services. Many OEM manufacturers also offer custom printing, logo placement, and accessory bundling options. The extent of customization depends on order quantities and manufacturer capabilities, with more options typically available for larger volume commitments.

What quality certifications should distributors expect from OEM manufacturers

Professional OEM manufacturers should provide certifications including material safety testing, burst resistance verification, and compliance with relevant international standards such as CE marking or CPSIA requirements. Environmental certifications for material composition and manufacturing processes are increasingly important for market acceptance. Third-party testing documentation and regular compliance audits demonstrate ongoing quality commitment.